Please note: All information required for this assignment is provided in the

Unit 3 Student Workbook

[Excel] for this unit.

Read the

Fashion Designs International, Inc.

[PDF] case study and complete the following requirements.

Quantitative Analysis:

Based on the information presented in Tables 1 and 2, calculate the following:

Qualitative Analysis:

In a 2-3 page report, based on your quantitative analysis, what do you think FDI should do with its production: continue in North America or move it overseas? Discuss the quantitative, qualitative, and ethical factors, if any, that come into play with this decision. Support your recommendation with a minimum of 3 academic resources.

CaseStudy

>Data

ashion Designs International, Inc.

1,

1,260 22,450 5,400 5,400 30,996 36,996 42,234 7,380 2,100 ehicle expenses

)

amount ( )

Cost of Goods Sold: V (6) x VC per unit

V units sold (6) x VC per unit 3.00% -50% V units sold (6) x VC per unit 3.00% -50% V units sold (6) x VC per unit 3.00% -50% V units sold (6) x VC per unit 3.00% -50% V units sold (6) x VC per unit 3.00% Operating Expenses: 0% F 0% F fixed annual cost x 1 0% x VC per unit

2.0% F 0% V same % 0% 1.5% F fixed monthly cost x 12 1.5% 0% 1.5% F fixed monthly cost x 12 1.5% 1.5% 0% 1.5% 0% 1.5% 0% 1.5% 0% 1.5% 0% 1.5% 0% 1.5% 20% 1.5% 0% 1.5% 0% 1.5% 0% F fixed monthly cost x 12 1.5% 0% 1.5% 1.5% 0% 2016 (b)

÷ CM/U

Adapted from IMA

IMA EDUCATIONAL CASE JOURNAL VOL. 11, NO. 4, ART. 2, DECEMBER 2018

ISSN 1940-204X

Fashion Designs International, Inc.

INTRODUCTION FDI, based in Greensboro, North Carolina, manufactures and distributes women’s apparel to retailers ALINA ROSSI, FASHION DESIGNER

Alina Rossi studied fashion design in Italy and, upon completing her studies, moved back to the United States APPAREL PRODUCTION

The production of FDI’s products is composed of three major phases: (1) manufacturing the fabric to be used A separate company, RossiDesigns LLC, owns the RossiDesigns brand name and trademarks. Rossi assigns

all of her designs to RossiDesigns LLC. As apparel pieces are distributed to retailers, FDI pays a royalty to

RossiDesigns LLC for the right to use the designs and the RossiDesigns brand name.1 The RossiDesigns label

is sewn into each piece that FDI produces.

FDI PROFITABILITY

FDI’s profitability is attributable to a lean company structure and Rossi’s talents and work ethic. The company, RILEY’S RESEARCH AND PREPARATION

As mentioned previously, all of FDI’s production activities are in North America: The fabric is produced in Riley believes that it is in the company’s best interest to move production overseas and that this course of convincing her to move the company’s production overseas. When he meets with Rossi, Riley’s challenges

include helping her focus on her financial goal, convincing her that achieving those goals will require tradeoffs

in production supervision, and convincing her that the tradeoffs will be well worth it.

Unit 3_Fashion Designs International, Inc. Adapted from IMA

IMA EDUCATIONAL CASE JOURNAL VOL. 11, NO. 4, ART. 2, DECEMBER 2018

ISSN 1940-204X

Fashion Designs International, Inc.

INTRODUCTION FDI, based in Greensboro, North Carolina, manufactures and distributes women’s apparel to retailers ALINA ROSSI, FASHION DESIGNER

Alina Rossi studied fashion design in Italy and, upon completing her studies, moved back to the United States APPAREL PRODUCTION

The production of FDI’s products is composed of three major phases: (1) manufacturing the fabric to be used A separate company, RossiDesigns LLC, owns the RossiDesigns brand name and trademarks. Rossi assigns

all of her designs to RossiDesigns LLC. As apparel pieces are distributed to retailers, FDI pays a royalty to

RossiDesigns LLC for the right to use the designs and the RossiDesigns brand name.1 The RossiDesigns label

is sewn into each piece that FDI produces.

FDI PROFITABILITY

FDI’s profitability is attributable to a lean company structure and Rossi’s talents and work ethic. The company, RILEY’S RESEARCH AND PREPARATION

As mentioned previously, all of FDI’s production activities are in North America: The fabric is produced in Riley believes that it is in the company’s best interest to move production overseas and that this course of convincing her to move the company’s production overseas. When he meets with Rossi, Riley’s challenges

include helping her focus on her financial goal, convincing her that achieving those goals will require tradeoffs

in production supervision, and convincing her that the tradeoffs will be well worth it.

Table 1

F

Comparative Income Statements

year ended December

3

201

4

201

5

201

6

Sales

$1,987,050

$2,124,885

$2,249,830

Cost of Goods Sold:

Fabric

237,250

250,390

264,260

Cutting

201,500

212,660

224,440

Sewing

260,000

274,400

289,600

Brand labels

3,900

4,116

4,344

Thread etc.

650

686

724

Shipping and freight

29,250

30,870

32,580

Total Cost of Goods Sold

732,550

773,122

815,948

Gross Profit

1,254,500

1,351,763

1,433,882

Operating Expenses:

Bank charges

1,260

1,320

Salary expense

350,000

360,000

370,500

Wage expense

263,250

291,722

323,275

Employee benefits – salaried employees

63,000

64,800

66,690

Employee benefits – hourly employees

31,590

35,007

38,793

Insurance

22,450

23,124

Information Technology services

8,220

8,340

8,520

Legal fees

15,000

18,840

20,280

Licenses and permits

5,400

Meals and entertainment

14,304

15,019

15,925

Printing and reproduction

1,452

1,740

1,860

Professional Fees

15,504

16,260

16,920

Marketing and promotion

30,996

34,104

Rent – Office

36,996

3

7,380

Rent – Warehouse

41,004

42,234

Repairs and maintenance

8,592

10,188

Security expense

2,100

2,184

Office supplies

2,136

2,532

2,844

Telephone and internet

2,472

2,604

2,808

V

5,760

5,875

6,051

Travel expenses

21,000

21,210

21,846

Utilities

1,956

2,034

2,156

Total operating expenses

944,442

997,907

1,051,295

Profit before taxes

310,058

353,856

382,587

Income taxes

93,017

106,157

114,776

Profit after taxes

$217,041

$247,699

$267,811

Table 2

Fashion Designs International, Inc.

Assumptions for Income and Expense Projections

Expense Item

F/V (

1a

Formula

2016

1b

Projected annual growth

Effect of overseas move

Fabric (2)

units sold

$7.30000

3.0

0%

-50%

Cutting (2)

$6.20000

Sewing (3)

$8.00000

Brand labels (4)

$0.12000

Thread etc. (1)

$0.02000

Shipping and freight (5)

$0.90000

300%

Bank charges F

fixed monthly cost x 12

$1,320

1.5%

Sal exp – owner

fixed annual cost x 1

$150,000

0.0%

Sal exp – employees

$220,500

2.0%

Wage expense V

units produced

$8.93025

–

20%

Emp benis – sal

salary expense x percentage

$66,690

same %

Emp benis – hrly

wage expense x percentage

$1.07163

Insurance F fixed annual cost x 1

$23,124

250%

IT services

$8,520

Legal fees F fixed monthly cost x 12

$20,280

200%

Lic & Permits

$5,400

75%

Meals and entertainment F fixed monthly cost x 12

$15,925

Printing and reproduction F fixed monthly cost x 12

$1,860

Professional Fees F fixed monthly cost x 12

$16,920

Marketing and promotion F fixed monthly cost x 12

$30,996

Rent – Office F fixed monthly cost x 12

$37,380

Rent – Warehouse F fixed monthly cost x 12

$42,234

Repairs and maintenance F fixed monthly cost x 12

$10,188

Security expense F fixed monthly cost x 12

$2,184

Office supplies F fixed monthly cost x 12

$2,844

Telephone and internet F fixed monthly cost x 12

$2,808

Vehicle expenses

$6,051

Travel expenses F

fixed quarterly cost x 4

$21,846

400%

Utilities F fixed monthly cost x 12

$2,156

1a

F = fixed cost; V = variable cost;

1b

for variable (V): amount per unit; for fixed (F): annual amount

2

cost paid on per yard basis ;

3

cost paid on per piece basis

4

cost paid on per label basis ;

5

cost paid on weight and volume basis

6

units sold and units produced both projected to grow at annual rate of 6%

Student Template

Fashion Designs International, Inc.

Global Assumptions:

units sold

36,200

units produced 36,200

avg sales price

$62.15

income tax rate

30%

benefits – salary

18.0%

benefits – wages

12.0%

Desired Cash Payout

(a) – Calculate Total Variable Costs

Total variable costs

(b) – Calculate Total Fixed Costs

Total fixed costs

(c) – Calculate Contribution Margin per Unit

Sales price per unit

Variable costs per unit (a)

Contrib margin per unit

(d) – Calculate Break-Even, Unit Sales

Fixed costs

÷ CM/U

Unit sales, BEP

(e) – Calculate Target Profit

Desired cash payout to owner (from scenario)

Subtract owner salary

Target profit after taxes

÷ 100% less income tax rate

Target profit before taxes

Fixed costs

FC + target profit

Unit sales, target profit

George Gonzalez, PhD, Assistant Professor Accounting

University of Lethbridge–Calgary Campus

Calgary, Alberta, Canada

“Balancing quantitative and qualitative factors can be quite a challenge,” Charles Riley thought to himself. Riley

is the CFO of Fashion Designs International, Inc. (FDI), a small women’s apparel business. The CEO and sole

shareholder of FDI, Alina Rossi, had asked Riley for suggestions about how to increase the company’s profits

to the level that matched her financial goals. Riley knew, however, that there were qualitative factors of

importance to Rossi that posed challenges.

worldwide under the brand name RossiDesigns. Headed by Rossi, an Italian-educated, award-winning fashion

designer with a high work ethic and a perfectionist streak, the company’s products are considered of excellent

quality by consumers and retailers. The designs, fabric, and processes used in production all contribute to this

high level of quality. Since its inception in 2001, the company has grown steadily to annual sales of US$2.25

million in 2016 (see Table 1).

where her family had emigrated when she was 10 years old. Rossi was a highly creative designer who almost

certainly could have done well by selling her designs to large international fashion companies but chose

instead to start her own company.

Rossi started her fashion business in 2001 by selling women’s apparel to small U.S.-based boutique shops.

Her designs—particularly popular with women in their 20s, 30s, and 40s—sold quickly, and her business grew

accordingly. After several years, her market expanded to include Canada, Mexico, and a few countries in

Europe.

Rossi tends to be a perfectionist both with her designs and in her insistence on high production quality. This

manifests itself in her close supervision of production processes, to a point of near-obsession with ensuring the

high apparel standards that she demands.

for apparel pieces, (2) cutting the fabric according to the particular apparel piece’s design, and (3) sewing the

cut fabric into apparel wear. FDI’s women’s outfits are made from high-quality fabric, which Rossi specifies to

the fabric manufacturer, a company based in Toronto, Ontario, Canada. Large rolls of fabric manufactured for

FDI are shipped to FDI’s warehouse in Greensboro, where they are stored until ready to be used in production

runs. At such time, fabric is sent to the cutting shop where the fabric is cut into large pieces of specific size and

shape, as specified by Rossi’s design. Finished cut pieces are then delivered to the sewing shop. In the sewing

process, cut pieces are sewn as prescribed by Rossi into final products, which is then transported to FDI’s

warehouse until ready for shipment to retailers (for instance, FDI’s main customers). The cutting and sewing

shops, independent from each other, are both located within a 50-mile radius of FDI’s main offices in

Greensboro.

however, has not achieved the level of profitability that Rossi desires. While her goal is an annual net cash

payout from the company of US$600,000, currently the net cash paid or available to her (for instance,

combined salary and net profit) is only about two-thirds that amount.2

Canada, and the cutting and sewing are done in the United States. Riley believes that the quickest and surest

way for FDI to increase its profitability is by moving manufacturing activities overseas to a low-cost country

where labor and other production costs would be significantly reduced.3 Based on his prior research, Riley has

estimated how the company’s costs would change if all manufacturing was moved overseas (see Table 2). He

has prepared a schedule of revenue and expense growth rates that allow him to project future net profits under

either scenario—for instance, keeping manufacturing in North America or moving it overseas (see Table 2,

“Projected Annual Growth” column). Riley determined the cost behavior of each item of expense based on cost

drivers and used this information to arrive at formulas for projecting each expense item (see Table 2, “Formula”

column).

action is the best way to reach Rossi’s goals for the company. He recognizes, however, that a big challenge in

convincing Rossi of this is her strong desire for close supervision of all production processes. Riley knows that

Rossi is a perfectionist, and he believes that other related aspects of Rossi’s personality represent potential

hurdles to an overseas move. Fashion design is, at its essence, an artistic skill. As with many artists, Rossi

probably views her company’s final product as an extension of herself. Riley imagines that Rossi’s pride and

ego are significant factors in her strong need for oversight and her obsession with production quality.

Riley knows that he will have to keep Rossi’s personality factors in mind if he is to have a good chance of

George Gonzalez, PhD, Assistant Professor Accounting

University of Lethbridge–Calgary Campus

Calgary, Alberta, Canada

“Balancing quantitative and qualitative factors can be quite a challenge,” Charles Riley thought to himself. Riley

is the CFO of Fashion Designs International, Inc. (FDI), a small women’s apparel business. The CEO and sole

shareholder of FDI, Alina Rossi, had asked Riley for suggestions about how to increase the company’s profits

to the level that matched her financial goals. Riley knew, however, that there were qualitative factors of

importance to Rossi that posed challenges.

worldwide under the brand name RossiDesigns. Headed by Rossi, an Italian-educated, award-winning fashion

designer with a high work ethic and a perfectionist streak, the company’s products are considered of excellent

quality by consumers and retailers. The designs, fabric, and processes used in production all contribute to this

high level of quality. Since its inception in 2001, the company has grown steadily to annual sales of US$2.25

million in 2016 (see Table 1).

where her family had emigrated when she was 10 years old. Rossi was a highly creative designer who almost

certainly could have done well by selling her designs to large international fashion companies but chose

instead to start her own company.

Rossi started her fashion business in 2001 by selling women’s apparel to small U.S.-based boutique shops.

Her designs—particularly popular with women in their 20s, 30s, and 40s—sold quickly, and her business grew

accordingly. After several years, her market expanded to include Canada, Mexico, and a few countries in

Europe.

Rossi tends to be a perfectionist both with her designs and in her insistence on high production quality. This

manifests itself in her close supervision of production processes, to a point of near-obsession with ensuring the

high apparel standards that she demands.

for apparel pieces, (2) cutting the fabric according to the particular apparel piece’s design, and (3) sewing the

cut fabric into apparel wear. FDI’s women’s outfits are made from high-quality fabric, which Rossi specifies to

the fabric manufacturer, a company based in Toronto, Ontario, Canada. Large rolls of fabric manufactured for

FDI are shipped to FDI’s warehouse in Greensboro, where they are stored until ready to be used in production

runs. At such time, fabric is sent to the cutting shop where the fabric is cut into large pieces of specific size and

shape, as specified by Rossi’s design. Finished cut pieces are then delivered to the sewing shop. In the sewing

process, cut pieces are sewn as prescribed by Rossi into final products, which is then transported to FDI’s

warehouse until ready for shipment to retailers (for instance, FDI’s main customers). The cutting and sewing

shops, independent from each other, are both located within a 50-mile radius of FDI’s main offices in

Greensboro.

however, has not achieved the level of profitability that Rossi desires. While her goal is an annual net cash

payout from the company of US$600,000, currently the net cash paid or available to her (for instance,

combined salary and net profit) is only about two-thirds that amount.2

Canada, and the cutting and sewing are done in the United States. Riley believes that the quickest and surest

way for FDI to increase its profitability is by moving manufacturing activities overseas to a low-cost country

where labor and other production costs would be significantly reduced.3 Based on his prior research, Riley has

estimated how the company’s costs would change if all manufacturing was moved overseas (see Table 2). He

has prepared a schedule of revenue and expense growth rates that allow him to project future net profits under

either scenario—for instance, keeping manufacturing in North America or moving it overseas (see Table 2,

“Projected Annual Growth” column). Riley determined the cost behavior of each item of expense based on cost

drivers and used this information to arrive at formulas for projecting each expense item (see Table 2, “Formula”

column).

action is the best way to reach Rossi’s goals for the company. He recognizes, however, that a big challenge in

convincing Rossi of this is her strong desire for close supervision of all production processes. Riley knows that

Rossi is a perfectionist, and he believes that other related aspects of Rossi’s personality represent potential

hurdles to an overseas move. Fashion design is, at its essence, an artistic skill. As with many artists, Rossi

probably views her company’s final product as an extension of herself. Riley imagines that Rossi’s pride and

ego are significant factors in her strong need for oversight and her obsession with production quality.

Riley knows that he will have to keep Rossi’s personality factors in mind if he is to have a good chance of

Essay Writing Service Features

Our Experience

No matter how complex your assignment is, we can find the right professional for your specific task. Achiever Papers is an essay writing company that hires only the smartest minds to help you with your projects. Our expertise allows us to provide students with high-quality academic writing, editing & proofreading services.

Free Features

Free revision policy

$10Free bibliography & reference

$8Free title page

$8Free formatting

$8How Our Dissertation Writing Service Works

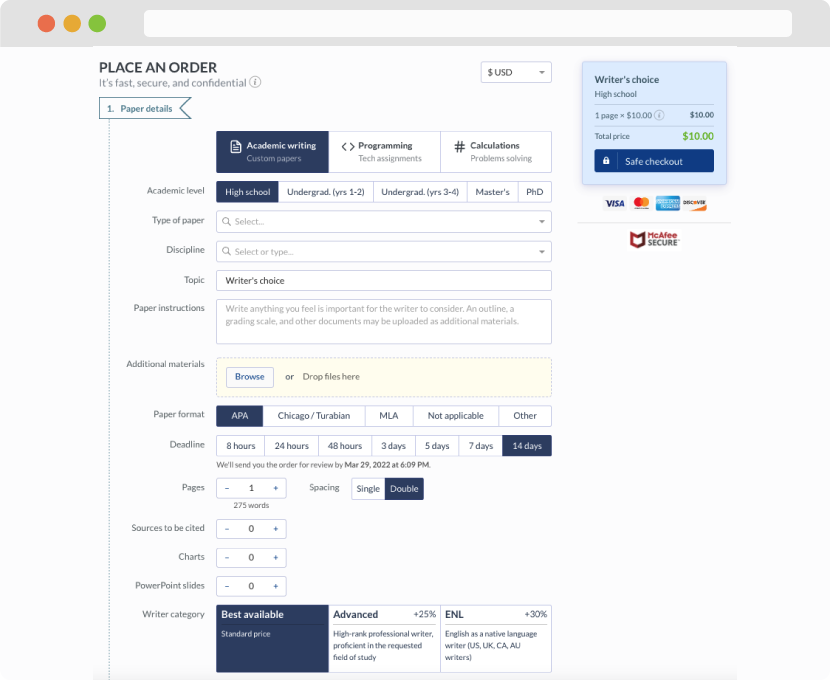

First, you will need to complete an order form. It's not difficult but, if anything is unclear, you may always chat with us so that we can guide you through it. On the order form, you will need to include some basic information concerning your order: subject, topic, number of pages, etc. We also encourage our clients to upload any relevant information or sources that will help.

Complete the order form

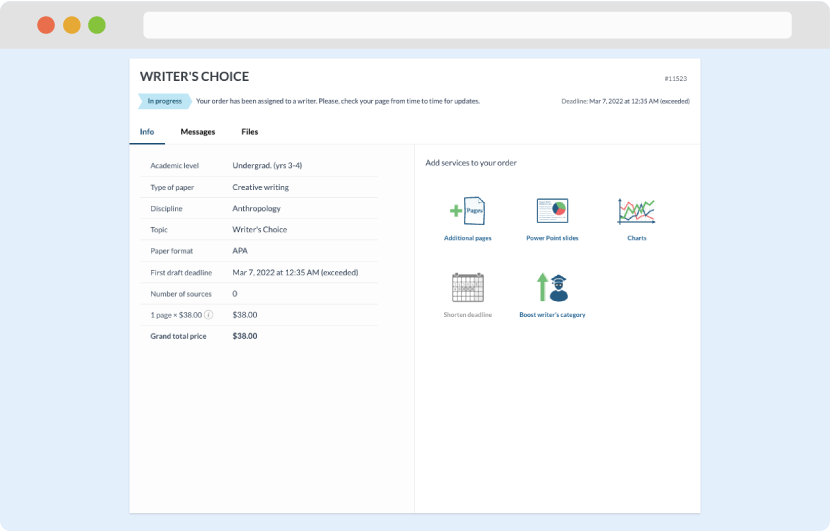

Once we have all the information and instructions that we need, we select the most suitable writer for your assignment. While everything seems to be clear, the writer, who has complete knowledge of the subject, may need clarification from you. It is at that point that you would receive a call or email from us.

Writer’s assignment

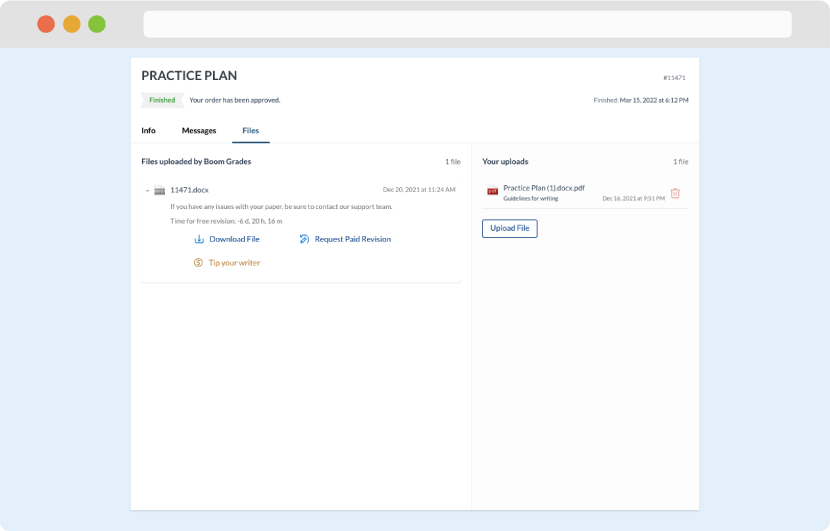

As soon as the writer has finished, it will be delivered both to the website and to your email address so that you will not miss it. If your deadline is close at hand, we will place a call to you to make sure that you receive the paper on time.

Completing the order and download