TASK: Please write an Executive Summary for the case: IKEA Case Report

Requirements: Max 1 page (A4), font size 12, double line space. Notice copying from each other is plagiarism

supply chain management

ACase Study of IKEA – in the

Interactive Framework of Green

Supply Chain Management

Someone’s or Research

Team’s Name

12 December 2018

1

Title Page

1. Executive Summary Page 2

2. Introduction

a. What is Supply Chain Management? Page

2

b. What is Green Supply Chain Management? Page 2

c. Why companies want to have Green Supply Chain Management? Page 2

d. Current Situation of GSCM Page 3

3. The Framework and Case Study

a. The Interactive Framework of GSCM Page 3

b. A Case Study of IKEA Page 4

c. Application of IKEA case into the Framework Page 5-7

i. Green Product Design

ii. Green Material Management

iii. Green Manufacturing

iv. Green Marketing and Distribution

v. Reverse Logistics

4. Challenges and Recommendations Page 8

5. Conclusion Page 8

2

1. Executive Summary

This is section is for your Assignment 1. It’s your job to fill

in this ES part.

Min: half page; Max: one page (12 font size, double space)

2. Introduction

a. What is Supply Chain Management?

Supply chain management is the management of the flow of goods and services and

includes all processes that transform raw materials into final products, from supplier to

manufacturer to wholesaler to retailer to consumer. (Supply Chain, 2019).

b. What is Green Supply Chain Management?

According to Srivastava (2007), GSCM can be defined as “integrating environmental

thinking into supply chain management” by minimizing wastages like emissions, energy, solid

waste in the supply chain, “including product design, material sourcing and selection,

manufacturing process, delivery of the final product to the consumers as well as end-of-life

management of the product after its useful life”.

c. Why companies want to have Green Supply Chain Management?

There are different factors to motivate companies to go “green” in their supply chain.

One of the factors is consumers’ awareness. Previous survey indicates that more than half of

global consumers (53 percent/representing 1.1 billion people) prefer to purchase products and

services from a company with a strong environmental reputation, according to a global survey

released by video-conferencing company Tandberg in 2007. Another study in 2015 also

showed people continued to be willing to pay extra for green products and services that come

from companies who are committed to positive social and environmental impact. Being “green”

3

can increase the reputations of the organizations which also get the supports from specific

consumers. GSCM can result cost reduction and profitability which is another motivator for

organizations to switch to “green” supply chain (Kumar, 2011).

d. Current Situation of GSCM

Top companies are now engaging in going “green”, not only due to the social

responsibility but these organizations also concern the future business environment (17 Top,

2019). For instance, The Bank of America has successfully recycled 30,000 tons of paper every

year. Coca Cola recycled or recovered more than 90% of waste materials at production facilities

in 2009 (Coca-Cola, 2011). Although studies have shown that implementation of GSCM can

result profitability (Kumar, 2011), companies still have hesitation in switching to the “green”

supply chain (Bhateja, 2011).

3. The Framework and Case Study

a. The Interactive Framework of GSCM

Ghobakhloo has developed an integrated framework of GSCM (Figure 1) which is based

on following definition of GSCM:

Green Supply Chain Management (GSCM) = Green Product Design + Green Material

Management + Green Manufacturing Process + Green Distribution and Marketing + Reverse

Logistics (RL)

4

Figure 1. Framework of green supply chain process implementation

b. A Case Study of IKEA

IKEA is a Swedish-founded furniture retailer that designs and sells ready-to-assemble

furniture, kitchen appliances and home accessories. IKEA’s vision is to ‘create a better

everyday life for many people’ and their business concept is ‘to offer a wide range of well-

designed, functional home furnishing products at prices so low that as many people as possible

will be able to afford them’ (IKEA Supply AG, 2008). The vision and business ideas are carried

across all aspects of the business, ‘We work hard to achieve quality at affordable prices for our

customers through optimising our entire value chain, by building long-term supplier

relationships, investing in highly automated production and producing large volumes. Our

5

vision also goes beyond home furnishing. We want to create a better every day for all people

impacted by our business.’ (Inter IKEA Systems B.V., 2015).

To achieve the above vision, IKEA announced commitments to inspire and enable

sustainable living in 2018. The company aims to remove all single-use plastic products from

the IKEA range globally by 2020, reduce 70% climate footprint per product and use all

renewable or recycled materials by 2030. To achieve these goals, IKEA is investing EUR 380

million to develop new materials and a truly circular IKEA range.

c. Application of IKEA case into the Framework

This section is going to briefly explain the detail of the framework and then apply the

IKEA case in it to explain how IKEA successfully develops and implements the GSCM.

i. Green Product Design

Green product design includes Life-Cycle Assessment/analysis (LCA) and

Environmentally Conscious Design (ECD) of the product. LCA is generally concerned with

the process for assessing and evaluating the environmental, occupational health and resource

consequences of a product through all phases of its life and ECD seeks to design products by

considering the environment (Gungor, 1999). In ECD context, the information from LCA can

transfer into the initial design of a new product. The designers from IKEA have the ECD idea,

they always implement sustainable innovation in their designs. In creating the ODGER chair,

the team implemented LCA, they carried out certain tests, well communicated with the

suppliers in matching the possibilities to fulfil customers’ need, result sustainability and keep

prices low (New ODGER, 2017).

ii. Green Material Management

6

It includes green material selection and green material sourcing. The most reasonable

action is replacing a potentially hazardous material by less problematic one (Srivastava, 2007)

or replacing limited resources by renewable or recycled materials. Using the same example,

ODGER chair, the chair is made of wood plastic composite, 30% renewable wood and 55%

recycled plastic.

According to IKEA’s annual report 2018, IKEA used around 0.7% of all cotton grown

around the world. Traditional farming techniques require large amounts of chemical fertilisers

and toxic pesticides which result soil erosion. As an investor of Treetotextile, this company has

developed process to transform wood pulp into a cotton-like fabric which has assisted IKEA

to manufacture a more environmental product.

IKEA also responds to sustainable sourcing; more and more products only contain

sustainably sourced wood. For instance, all wood used in the furniture series HAVSTA comes

from sustainably managed forests.

iii. Green Manufacturing

It consists of resource consumption reduction, waste reduction and emission reduction.

The main objective in the green manufacturing process is to reduce the usage of materials and

the indirect resources/energies (Ghobakhloo, 2013). To minimize the unnecessary waste in

production, IKEA cuts and shapes every piece of wood with designs and plans. For instance,

SKOGSA worktop is made with a thin layer technique, placing a 3mm solid wood surface on

particle board. This technique requires less raw material than the ordinary solid worktop.

The organization also pays efforts on reducing the emission of carbon dioxide. IKEA

Group has invested EUR 1.7 billion in renewable energy since 2009. It is operating 416 offsite

wind turbines and has installed around 750,000 solar panels on IKEA buildings (Circular and

Climate, 2018).

7

iv. Green Marketing and Distribution

Green marketing consists of promoting products and services based on environmental

factors or awareness. Companies hope that consumers will associate the environmental core

values with the company or brand, which can help to cater a new target group (Green Marketing,

2018). For instance, IKEA includes the latest sustainability information in the website to

promote their products and brand. The Group has announced to phase out single-use plastic

products by 2020 (IKEA commits, 2018). The 3 stores in Hong Kong has stopped providing

plastic bags for consumers.

Green distribution defined as; ”transportation service that has a lesser or reduced negative

impact on human health and the natural environment when compared with competing

transportation services that serve the same purpose” (Björklund, 2010). For instance, IKEA

cooperated with particle-board producers to create a new particle-board alternative. The new

boards reduced the need for resources by 85,816 tons; on the other hand, the weight of cargo

and number of trucks dropped, finally resulted less carbon emission and helped IKEA lower

costs (Design for, 2018).

v. Reverse Logistics

Recycling, reusing and remanufacturing of materials are under reverse logistics.

Recycling is the process of collecting and processing materials that would otherwise be

thrown away as trash and turning them into new products (Recycling, 2018). IKEA encourages

consumers to recycle cardboard, drinks containers, betteries and light bulbs by placing them in

recycling bins at stores.

Reuse is defined as to use an item more than once. IKEA has just implemented a new

scheme of exchanging used IKEA furniture for a reward voucher in Edinburgh. The company

will sell the items in the bargain area (IKEA to sell, 2019).

8

Remanufacturing refers to extend the life of the original core unit by repairing,

refurbishing or overhauling the item (Ghobakhloo, 2013). In 2019, Premier Sustain shared its

experience about remanufacturing office furniture with IKEA which is a pioneer project.

4. Challenges and Recommendations

One of the visions of IKEA is to provide quality products at affordable prices for our

customers. However, according to the annual report in 2018, due to the increased raw material

prices for wood and metal products, it led to an approximately 1% lower gross margin and an

0.2% price increase to IKEA retailers.

Reduction in gross margin definitely results a negative impact to the company’s financial

performance. Practising GSCM initially is a costly affair, since it is a long-term investment,

IKEA needs a longer time to see the result. To cope with this challenge, sourcing of new

suppliers and educations for suppliers maybe useful. IKEA can keep looking for new suppliers

which can provide sustainable resources. At the same time, the Group can establish a long-term

relationship with suppliers in assisting them to improve their manufacturing process in order

to reduce costs.

Increasing of retail price may influence customers’ decision making in purchasing

products. Many customers may not be willing to pay more for green products. To overcome

this challenge, IKEA can pay more effort in green marketing.

5. Conclusion

This paper briefly explains the framework and analyses how IKEA successfully develops

and implements the GSCM within the organization by using the framework. Apart from the

organization itself, cooperating with suppliers (in products design, sourcing & manufacturing)

and consumers (in marketing and reverse logistics) is also required.

9

Reference

17 Top Companies That are Going Green in 2019. (2019). Retrieved from

53% Of Consumers Prefer To Buy From Company With Green Rep. (2007). Retrieved from

https://www.environmentalleader.com/2007/10/53-of-consumers-prefer-to-buy-from-

companies-with-green-rep/

Bhateja, A., Babbar, R., Singh, S. and Sachdeva, A (2011). Study of Green Supply Chain

Management in the Indian Manufacturing Industries: A Literature Review cum an Analytical

Approach for the measurement of performance. International Journal of Computational

Engineering & Management, Vol 13

Bhattacharjee, K. (2015). green supply chain management- challenges and opportunities.

Retrieved from Amity Global Business School, Applies Economics & Commerce Web site:

https://www.researchgate.net/publication/317936918_Green_Supply_Chain_Management-

Challenges_and_Opportunities

Circular and Climate Positive. (2018). Retrieved from

https://www.ikea.com/ms/en_JP/this-is-ikea/people-and-planet/energy-and-

resources/index.html#value-not-waste

Coca-Cola: A Case Study In Sustainability. (2011). Retrieved from

Design for Everyone. (2018). Retrieved from

http://www.ikea.com/ms/en_JP/this-is-ikea/democratic-design/

https://www.environmentalleader.com/2007/10/53-of-consumers-prefer-to-buy-from-companies-with-green-rep/

https://www.environmentalleader.com/2007/10/53-of-consumers-prefer-to-buy-from-companies-with-green-rep/

https://www.researchgate.net/publication/317936918_Green_Supply_Chain_Management-Challenges_and_Opportunities

https://www.researchgate.net/publication/317936918_Green_Supply_Chain_Management-Challenges_and_Opportunities

https://www.ikea.com/ms/en_JP/this-is-ikea/people-and-planet/energy-and-resources/index.html#value-not-waste

https://www.ikea.com/ms/en_JP/this-is-ikea/people-and-planet/energy-and-resources/index.html#value-not-waste

https://www.environmentalleader.com/2011/08/coca-cola-a-case-study-in-sustainability/

http://www.ikea.com/ms/en_JP/this-is-ikea/democratic-design/

10

Ghobakhloo, M., Tang, S. H. & Zulkifli, N. (2013). An Integrated Framework of Green

Supply Chain Management Implementation,4(1). Retrieved from http://ijimt.org/papers/364-

K3001

Green Generation: Millennials Say Sustainability is A Shopping Priority. (2015). Retrieved

from https://www.nielsen.com/eu/en/insights/news/2015/green-generation-millennials-say-

sustainability-is-a-shopping-priority.html

Inter IKEA Group Financial Summary FY18. (2018). Retrieved from

https://preview.thenewsmarket.com/Previews/IKEA/DocumentAssets/525318

Inter IKEA Holding B.V. Annual Report FY18. (2018). Retrieved from

https://preview.thenewsmarket.com/Previews/IKEA/DocumentAssets/525222

IKEA to Sell Refurbished Furniture to Boost Culture of Recycling. (2019). Retrieved from

https://www.theguardian.com/business/2019/feb/07/ikea-to-sell-refurbished-furniture-in-bid-

to-boost-culture-of-recycling

M. Björklund, Journal of Purchasing and Supply Management, vol. 17,pp. 11-22, 2010.

A. Gungor and S. M. Gupta, Computers and Industrial Engineering, vol. 36, pp. 811-853,

1999.

New ODGER Chair. (2017). Retrieved from

Premier Shares Remanufacturing Best Practice With IKEA. (2019). Retrieved from

https://www.premierworkplaceservices.co.uk/premier-shares-remanufacturing-best-practice-

with-ikea/

http://ijimt.org/papers/364-K3001

http://ijimt.org/papers/364-K3001

https://www.nielsen.com/eu/en/insights/news/2015/green-generation-millennials-say-sustainability-is-a-shopping-priority.html

https://www.nielsen.com/eu/en/insights/news/2015/green-generation-millennials-say-sustainability-is-a-shopping-priority.html

https://www.investopedia.com/terms/g/green-marketing.asp

https://preview.thenewsmarket.com/Previews/IKEA/DocumentAssets/525318

https://preview.thenewsmarket.com/Previews/IKEA/DocumentAssets/525222

https://www.theguardian.com/business/2019/feb/07/ikea-to-sell-refurbished-furniture-in-bid-to-boost-culture-of-recycling

https://www.theguardian.com/business/2019/feb/07/ikea-to-sell-refurbished-furniture-in-bid-to-boost-culture-of-recycling

https://www.premierworkplaceservices.co.uk/premier-shares-remanufacturing-best-practice-with-ikea/

https://www.premierworkplaceservices.co.uk/premier-shares-remanufacturing-best-practice-with-ikea/

11

Ikea commits to phase out single-use plastic products by 2020. (2018). Retrieved from

https://www.theguardian.com/business/2018/jun/07/ikea-commits-to-phase-out-single-use-

plastic-products-by-2020

IKEA Supply AG. (2008). IWAY Standard. INGKA Holding B.V. IKEA. Retrieved from

http://www.ikea.com/gb/en/doc/general-document/ikea-

iwaystandard- __1364450371470

Recycling Basics. (2018). Retrieved from

https://www.epa.gov/recycle/recycling-basics

Srivastava SK. (2007). Green supply chain management: a state-of-the-art literature review.

International Journal of Management Reviews; 9(1): 53-80.

Sameer Kumar , Steve Teichman & Tobias Timpernagel (2012) A green supply chain is a

requirement for profitability, International Journal of Production Research, 50:5, 1278-1296,

DOI: 10.1080/00207543.2011.571924

Supply Chain Management (SCM). (2019). Retrieved from

https://www.investopedia.com/terms/s/scm.asp

https://www.theguardian.com/business/2018/jun/07/ikea-commits-to-phase-out-single-use-plastic-products-by-2020

https://www.theguardian.com/business/2018/jun/07/ikea-commits-to-phase-out-single-use-plastic-products-by-2020

http://www.ikea.com/gb/en/doc/general-document/ikea-iwaystandard- __1364450371470

http://www.ikea.com/gb/en/doc/general-document/ikea-iwaystandard- __1364450371470

https://www.epa.gov/recycle/recycling-basics

https://www.investopedia.com/terms/s/scm.asp

https://www.environmentalleader.com/2011/08/coca-cola-a-case-study-in-sustainability/

Green Marketing. (2018). Retrieved from

https://www.investopedia.com/terms/g/green-marketing.asp

What is an Executive Summary ?

🔷 An executive summary previews the main points of an

extended business document

🔷 It is written for nontechnical readers who don’t have time to

read the whole document or interest readers to read

the whole document

🔷 It contains enough information for a reader to get

familiarized with what is presented in the full document

without having to read it

4

Features:

Sufficient information

Providing an overview of a long

document or presentation with a

clear enough understanding that

the reader can make a decision

based alone

Intrigue readers

Creates value for the reader

as a first impression and

generates interest in

viewing the rest of the

content

Can Stand Alone

Conveying key points

and conclusions

Keep Simple & Short

Usually no more than

5

~10% of the main

report

5

7

Write the summary after you write or familiarize the main

report, and make sure it is no more than 5~10% the length

of the main report

7 Steps : Write a simple declarative and appealing sentence for each

of the main points, as directly as possible

Capture the purpose and the main conclusions or

recommendation(s) in one or two sentences

List the main or key points the summary will cover in the

same order they appear in the main report

Close with a brief summary and reiteration of the main idea

Read the summary slowly and critically, making sure it

conveys your purpose, message and key recommendations.

Make sure the readers to be able to skim the summary

without missing the point of the main report

Double check for errors of style, spelling, grammar and

punctuation. Ask help to proof read and edit the document

1

3

4

5

6

7

2

8

An Example

Problems

Facing

Ford

Executive Summary

The environment in which the automobile industry operates is continuously

evolving. Perhaps no one knows this better than Ford Motor Company. Until

recently, Ford was able to operate with a fundamentally flawed business

structure; however, its failure to reconcile weaknesses was highlighted

because of increased competition and gas prices. Going forward, Ford needs

to focus on strengthening its fundamentals and streamlining its business

processes, as well as developing technology to better serve the growing

demand for greater fuel economy.

Problems Facing Ford

The fundamentals that Ford failed to execute include managing costs,

maintaining good supplier relations, utilizing internal resources, and planning

for the future.

• In

20

06, Ford spent $3.5 billion on insurance benefits for 570,000 current and past

employees, adding $1200 to the ticket price of each car.

• Rather than striving for a mutually beneficial relationship with its suppliers, Ford

takes the “crush their bones” approach, forcing unrealistic price reductions that

squeeze the suppliers, often driving them into bankruptcy. This approach is

detrimental because Ford’s high expectations can lead to lower quality goods as

suppliers try to meet Ford’s requirements.

• Until 2006, Ford was structured so that each regional unit operated autonomously.

This breakdown of communication made business inefficient.

• The unprecedented growth in models vying for customers in the U.S. has ended

the Big Three as we know it. In 2002, there were 215 models and a 50 percent

increase is expected by the decade’s end.

Recommendations for Ford

It is necessary to develop a set of best practices and capitalize on opportunities for

future growth by doing the following:

• Adopt an open book management approach when negotiating with unions

and employees to reduce its employee health care and pension costs.

• Benchmark Toyota’s supplier relations and production line efficiency.

• Capitalize on its reputation as America’s number one selling truck for the past

31 years, by incorporating hybrid technology into its light truck segment.

Conclusion

Ford’s fundamental weaknesses include cost management, supplier relations,

utilization of internal resources, and planning for the future. To address these

problems, Ford needs to adopt an open book management approach, develop a

set of best practices that parallels the business processes of efficient industry

players, and become the number one producer of hybrids in the light truck

segment.

Title

Introduction

Paragraph

Statement of main

problems and

explanation

Concluding

Paragraph

Statement of main

recommendations

9

An Example

The environment in which the automobile industry operates is

continuously evolving. Perhaps no one knows this better than

Ford Motor Company. Until recently, Ford was able to operate

with a fundamentally flawed business structure; however, its

failure to reconcile weaknesses was highlighted because of

increased competition and gas prices. Going forward, Ford

needs to focus on strengthening its fundamentals and

streamlining its business processes, as well as developing

technology to better serve the growing demand for greater fuel

economy.

Problems

Facing

Ford

Introduction

Paragraph

10

An Example

The fundamentals that Ford failed to execute include managing costs,

maintaining good supplier relations, utilizing internal resources, and

planning for the future.

In 2006, Ford spent $3.5 billion on insurance benefits for 570,000 current

and past employees, adding $1200 to the ticket price of each car.

Rather than striving for a mutually beneficial relationship with its suppliers,

Ford takes the “crush their bones” approach, forcing unrealistic price

reductions that squeeze the suppliers, often driving them into bankruptcy.

This approach is detrimental because Ford’s high expectations can lead to

lower quality goods as suppliers try to meet Ford’s requirements.

Until 2006, Ford was structured so that each regional unit operated

autonomously. This breakdown of communication made business

inefficient.

The unprecedented growth in models vying for customers in the U.S. has

ended the Big Three as we know it.

In 2002, there were 215 models and a 50 percent increase is expected by

the decade’s end.

Problems

Facing

Ford

Statement of main

problems and

explanation

11

An Example

It is necessary to develop a set of best practices and capitalize

on opportunities for future growth by doing the following:

Adopt an open book management approach when negotiating with unions

and employees to reduce its employee health care and pension costs.

Benchmark Toyota’s supplier relations and production line efficiency.

Capitalize on its reputation as America’s number one selling truck for the past

31 years, by incorporating hybrid technology into its light truck segment.

Problems

Facing

Ford

Ford’s fundamental weaknesses include cost management, supplier relations,

utilization of internal resources, and planning for the future. To address these

problems, Ford needs to adopt an open book management approach, develop

a set of best practices that parallels the business processes of efficient industry

players, and become the number one producer of hybrids in the light truck

segment.

Concluding

Paragraph

Statement of main

recommendations

A Few Tips

1

The Executive

Summary is all

about getting

critical

information into

a boss’s hands so

s/he can make a

decision. Keep it

as short and as

complete as

possible.

2

Keep your main

points in mind as

you write the

summary. You do

not need to include

every point in the

summary, but

ensure that the

major ideas are

covered succinctly.

3

No need to cite

references, but if you are

summarizing another

work, introduce the

document in the opening

paragraph. Provide

enough reference

information for your

reader to easily find the

original document.

12

4

The most important

outcome of an

Executive Summary is

that the reader would

be able to make a

decision based

exclusively on the

information

presented in the

Executive Summary.

A longExecutive Summary – 2 pages

A lo

ng

Exe

cuti

ve

Sum

mar

y –

2

pag

es

PPT

Executive

Summary

• Highlights

• Easy for “quant.” analysis

19

Remember

Executive

Summary is a

Potential

Winner!

The most important outcome of

an Executive Summary is that the

reader would be able to make a

decision based exclusively on the

information presented in the

ExecutiveSummary.

Executive Summary precedes

your business plans, resume,

documents of great

importance, etc. Thus, it is of

utmost importance that the

executive summary is full-

proof without any error and

contains only important

matters.

20

21

Assignment #1

— Executive Summary

Ø Max 1 Page; Font 12 with double space;

Ø Due: Feb 2 (Wed) by 12pm (noon)

Essay Writing Service Features

Our Experience

No matter how complex your assignment is, we can find the right professional for your specific task. Achiever Papers is an essay writing company that hires only the smartest minds to help you with your projects. Our expertise allows us to provide students with high-quality academic writing, editing & proofreading services.

Free Features

Free revision policy

$10Free bibliography & reference

$8Free title page

$8Free formatting

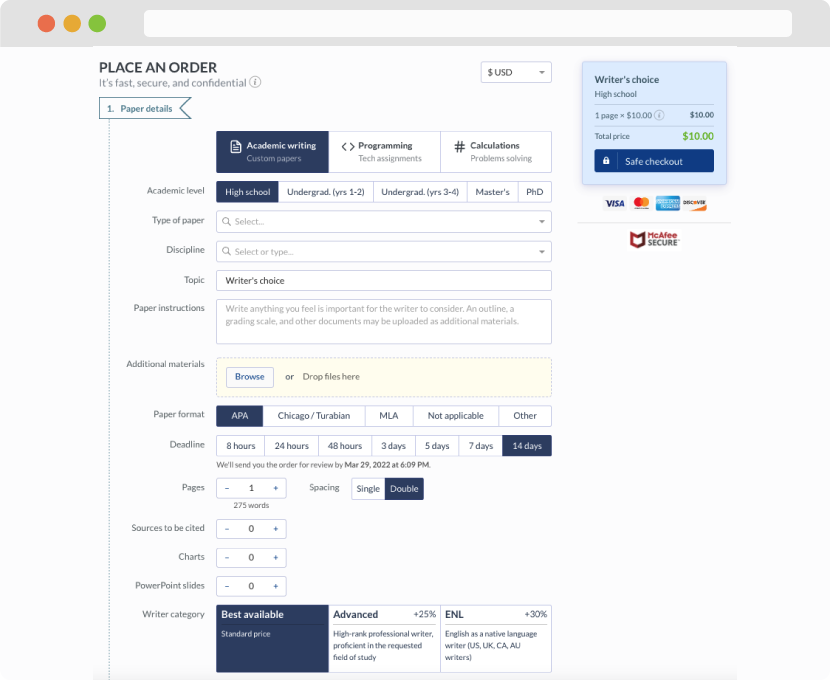

$8How Our Dissertation Writing Service Works

First, you will need to complete an order form. It's not difficult but, if anything is unclear, you may always chat with us so that we can guide you through it. On the order form, you will need to include some basic information concerning your order: subject, topic, number of pages, etc. We also encourage our clients to upload any relevant information or sources that will help.

Complete the order form

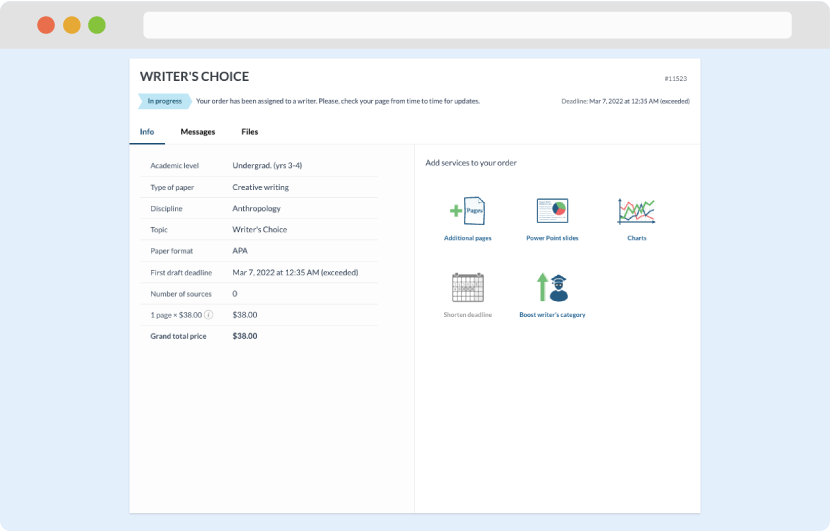

Once we have all the information and instructions that we need, we select the most suitable writer for your assignment. While everything seems to be clear, the writer, who has complete knowledge of the subject, may need clarification from you. It is at that point that you would receive a call or email from us.

Writer’s assignment

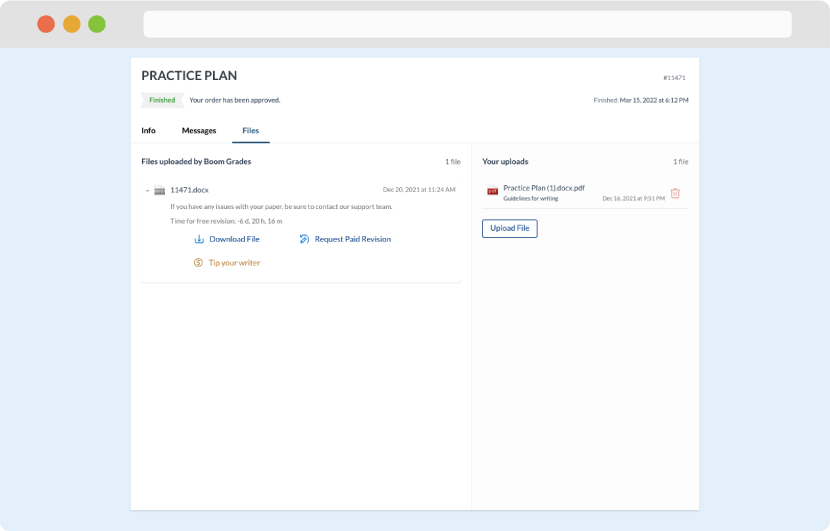

As soon as the writer has finished, it will be delivered both to the website and to your email address so that you will not miss it. If your deadline is close at hand, we will place a call to you to make sure that you receive the paper on time.

Completing the order and download