essay

22 S u p p l y C h a i n M a n a g e m e n t R e v i e w • M a y / J u n e 2 0 1 8 scmr.com

DEL

I

VERY RETURNS PACKAGING E-COMMERCE OUTSOURCING

THE

CIRCULAR

SUPPLY

CHAIN

t’s a law of gravity that what goes up must

come down. The corollary for e-commerce

is that much of what goes out will come

back—think of it as a circular supply chain.

Or, as the Wall Street Journal put it last Febru-

ary: “Retailers still celebrating their strongest

holiday sales in years now face the less-pleas-

ant task of disposing of billions of dollars in

returned merchandise.”

In the same article, Zac Rogers, an opera-

tions and supply chain professor at Colorado

State University, estimated that post-retail

sales, which includes returns and over-stock

BY JUDD ASCHENBRAND, MICHAEL MIKITKA,

TONY SCIARROTTA AND BOB TREBILCOCK

The boom in e-commerce has led

to a record number of returns. How

is that affecting supply chains and

what are the best practices amongst

industry leaders? To find out, SCMR

partnered with the Reverse Logistics

Association and WERC to survey our

readers and their members.

I

scmr.com S u p p l y C h a i n M a n a g e m e n t R e v i e w • M a y / J u n e 2 0 1 8 23

Judd Aschenbrand is the director of research for Peerless Research Group and can

be reached at jaschenbrand@peerlessmedia.com. Michael Mikitka is the CEO of the

Warehouse Education Research Council, or WERC, and can be reached at mmikitka@

werc.org. Tony Sciarrotta is the executive director of the Reverse Logistics Association and

can be reached at tony@ria.org. Bob Trebilcock is the editorial director of Supply Chain

Management Review and can be reached at btrebilcock@peerlessmedia.com.

24 S u p p l y C h a i n M a n a g e m e n t R e v i e w • M a y / J u n e 2 0 1 8 scmr.com

Reverse logistics

items, is growing at an estimated 7.5% a year. Mean-

while, Optoro, a third-party logistics provider, estimated

that roughly 13%, or $90 billion, of this year’s holiday

sales, would pass through the reverse supply chain by

the end of February.

While that estimate includes all verticals, in some

fashion categories, such as shoes, the returns rate is esti-

mated to be as high as 70%. Amy Augustine, the senior

manager of reverse logistics for U.S. Cellular, estimates

that her organization handled nearly 550,000 returned

electronic devices and accessories in 2017 (see sidebar).

Those devices all had to be shipped, received, inspected

and resold or disposed of in a way that delivers value to

the organization.

At U.S. Cellular, reverse logistics is a mature operation.

Augustine has been in her role for five years, with clear

lines of responsibility. Not only does she have a

team reporting directly to her, there is a line of

command to the C suite. “Our leadership is aware

that there is a cost associated with reverse logis-

tics,” says Augustine. “They want to understand

the holistic picture from soup to nuts.” Augustine

points out that reverse logistics was cash flow posi-

tive last year.

But is U.S. Cellular the exception or the rule?

Do most organizations have an executive who

owns the reverse logistics process? Have most

organizations implemented best practices for

handling and disposing of returns in a manner

that delivers value? Is the executive suite aware

of the costs and potential revenue to be gleaned

from returns? And, if not, are organizations pre-

paring for the future or just muddling through?

Those are among the questions the Reverse

Logistics Association, Supply Chain Management

Review and WERC set out to answer in a

recent survey of readers and members (see

“About our research”).

Our bottom line: Organizations like U.S. Cellular

that are paying attention to returns are realizing a ben-

efit that either adds to or minimizes the hit to their

bottom line. At the same time, the U.S. Cellulars of

the world are the exceptions and not the rule as too few

organizations are devoting sufficient resources to their

reverse logistics processes.

The who’s who of reverse logistics

One of the truisms of business, attributed to management

guru Peter Drucker, is that what gets measured gets man-

aged. Now, truth be told, Drucker went on to add that

the practice is true “even when it’s pointless to measure

and manage it …” We would argue that when it comes to

the sheer volume of returns coupled with the growth of

e-commerce, failing to measure the logistics, labor and

revenue associated with reverse logistics is far from point-

less—it’s no longer an option.

Survey respondents do recognize that when done right,

reverse logistics delivers value to the organization. Nearly

two-thirds, for instance, cited improved customer service

and satisfaction as a benefit of their reverse logistics pro-

cesses, followed by less waste (40%) and tangible cost

savings (36%) At the same time, just 60% said that reverse

logistics was extremely important (26%) or very important

(34%) to their company. You have to wonder why.

The first step in raising the visibility of returns is having

someone responsible for the process. Yet, based on survey

responses, in many respects returns and reverse logistics

is an orphaned function, with no one clearly claiming

parental responsibility. Only 17% reported that they

had a department dedicated to reverse logistics and

FIGURE 1

How important is reverse logistics

to your organization?

Extremely important 26%

Very important 34%

Somewhat important 28%

Not very/Not at all important 12%

63%

40%

36%

33%

32%

27%

20%

15%

Improved customer service/satisfaction

Less waste

Tangible cost savings

We’ve improved inventory tracking

We’ve improved product quality/design

We’ve improved packaging

A reduction in labor/man-hours

Other

scmr.com S u p p l y C h a i n M a n a g e m e n t R e v i e w • M a y / J u n e 2 0 1 8 25

another 16% responded that reverse logistics was organized

under a single group or department—which might have other

priorities. The latter ranged from logistics (31%) to distribu-

tion (16%) to supply chain (14%) to sales (7%). Nearly 60%

responded that reverse logistics is handled across more than one

department, ranging from logistics (55%) to sales (30%) to finance

(14%) to product marketing (7%).

The titles of respondents, which ranged from corporate

directors to operations managers to purchasing manag-

ers, reflects that diversity. Indeed, only 9% of respondents

were managers or directors of reverse logistics. You can read

more about the breakdown of respondents in the “About our

research” sidebar.

Perhaps the most telling response was that more than two-

thirds of respondents (68%) said that no one at the corporate

level in their company was responsible for reverse logistics. Nor

are senior leaders overseeing the process as a rule: Only 15%

of the reverse logistics managers reported to a vice president of

operations while only 13% each reported to the CEO or presi-

dent and only 9% reported to a vice president of supply chain.

Rather, the responsibility for reverse logistics was largely

doled out to department managers (44%) or supervisors (13%)

in logistics, warehousing, inventory management and other

departments associated with traditional supply chain manage-

ment functions. Senior leaders at the president/CEO (16%) or

vice president (18%) level accounted for just over one-third of

respondents. The list of titles to whom the individual in charge

of reverse logistics reported was equally diverse, with some 26

titles; the question of who else was involved in reverse logis-

FIGURE 2

Does your company have someone

on a corporate/C-level who is

responsible for reverse logistics?

Peerless Research Group (PRG)

Yes 32%

No 68%

About our research

This research was conducted in January 2018 by Peerless

Research Group on behalf of the

Reverse Logistics Association,

Supply Chain Management Review

and the Warehousing Education

and Research Council. The study

was conducted to better under-

stand how organizations are han-

dling their reverse logistics opera-

tions. The results are based on 272

qualified respondents and has a

margin of error of +/- 6.1%.

R e s p o n d e n t s re p re s e n t e d a

broad range of titles, including cor-

porate/divisional director (11%),

VP/general manager (14%), logis-

tics/distribution director/manager

(19%), warehouse/DC director/

manager (8%), supply chain direc-

tor/manager (7%), operations direc-

tor/manager (7%), reverse logistics/

returns director/manager (9%) and

purchasing director/manager (2%).

An additional 23% of respondents

listed their title as engineer, inven-

tory control manager, logistics su-

pervisor, owner, product engineer,

purchasing and logistics manager,

sales or shipping supervisor.

More than one-third of respon-

dents were manufacturers (34%),

followed by 3PLs and transporta-

tion/warehousing service providers

(33%), wholesale distributors (12%),

retailers (7%), e-tailers (6%) and

consultants (6%). More than one-

third (34%) listed their primary busi-

ness as business-to-business while

11% noted that they primarily sold

directly to consumers; the remaining

55% sold into both channels. The

average revenue of respondents was

$862.7 million, with 27% indicating

revenues of more than $1 billion; at

the other end of the scale, 37% indi-

cated revenues of less than $50,000.

26 S u p p l y C h a i n M a n a g e m e n t R e v i e w • M a y / J u n e 2 0 1 8 scmr.com

Reverse logistics

tics operations produced a list of 50 other titles.

The impression is that while the number of returns

continues to grow, reverse logistics is largely in the hands

of mid-level managers, with responsibility spread across a

multitude of departments and with little oversight at the

senior level.

Returns basics

The “make or buy” decision could be one of the most

important decisions related to any logistics or distribution

function. In the case of reverse logistics, more than two-

thirds of respondents (68%) are handling their returns

operations in-house and another 2% indicated that they

outsource now but plan to pull those tasks back under

their control. Meanwhile, 13% responded that they out-

source all of their reverse logistics operations and an

equal percentage outsource some tasks but keep others

in-house. Only 4% of those who currently do it in-house

plan to outsource to a 3PL in the future.

Why do it yourself? More than half (54%) said it

allows them to keep better control, while 51% said they

can be more responsive to customers, 47% have the

resources to handle in-house and 45% believe they can

do it for less expense.

Of those currently outsourcing, 60% said it is not their

core competency and an equal percentage believe it’s more

cost-effective to outsource. Interestingly, 38% believe that

a 3PL can be more responsive to customers, 33% said they

just don’t have the resources or labor to do it in house, and

25% are limited by space in their facilities.

Regardless of who handles returns, a surprising 39%

of respondents said they have no visibility into returns—

they just show up. A similar number (38%) receive sched-

uled reports and 32% track point of sale information at

their returns center.

More surprising, 40% of respondents couldn’t deter-

mine how much reverse logistics is saving their company

and another 36% aren’t sure. Only 24% said they were

able to determine how much their reverse logistics opera-

tion is saving their company, with an estimated average

annual revenue savings of 16.5%.

Some 44% of respondents accept returned items at a ful-

fillment or returns center, and another 15% of respondents

said they were 3PLs who handle reverse logistics tasks for

their customers, presumably at the 3PLs distribution center.

Three-fourths of respondents don’t expect that to change in

the next two years.

More than 70% of respondents are collecting information

regarding returned items, and another 15% say they some-

times collect information. In fact, only 11% said that they

never collect information about returned items. The most

common collected data among retailers (R) and manufactur-

ers (M) included who is returning the item (81% – R, 92%

– M), the model number (79% – R, 81% – M) and the date

sold (60% – R, 64% – M). Retailers were also collecting if the

customer is a repeat returner (60%), where the item was pur-

chased (44%) and how the item was purchased (35%), while

57% of manufacturers were also collecting the serial number.

The number one reason for returns, noted by 59% of

respondents, was defective merchandise, estimated to

account for 16.3% of returns. Forty-two percent of respon-

dents identified buyer’s remorse as a reason for returns while

29% noted that the product wasn’t what the customers was

expecting or that the product had been misrepresented as a

reason for returns.

The most common challenges associated with process-

ing returns: Damaged goods (52%), no reason given for a

return (40%), missing parts (38%), incorrect or inaccurate

manifests (36%), and a reverse logistics process that needs

improvement (33%).

Last, respondents are utilizing a multitude of channels

for the disposition of returned items that are in re-sellable

condition, ranging from putting the item back on the shelf

or a liquidation sale (both at 56%), selling to a discount

retail chain such as Big Lots (21%), auctioning off inventory

(18%) and utilizing a dedicated page on the company web-

FIGURE 3

Are you able to determine how

much your reverse logistics

operation is saving your company?

Peerless Research Group (PRG)

24%*

Yes

40%

No

36%

Not sure

* These companies claim their reverse

logistics operation is yielding, on average,

revenue savings of 16.5% annually.

scmr.com S u p p l y C h a i n M a n a g e m e n t R e v i e w • M a y / J u n e 2 0 1 8 27

site (9%). Other channels mentioned included charitable

donations, outlet stores, refurbished and discounted, sell-

ing or giving away to employees and destroying.

Digital returns

Few of us would challenge the notion that e-commerce

is affecting the way we do business and order fulfillment.

Given easy return policies, there is certainly the perception

that e-commerce is having an impact on reverse logistics

processes. That is borne out by the 75% of respondents who

said that the number of returns they are dealing with has

increased and that e-commerce has affected their ability to

manage their reverse logistics operations (39%). Only 28%

of respondents indicated that their reverse logistics platform

is very prepared to handle a growing e-commerce business,

while 53% said they are

somewhat prepared.

At the same time, 62%

of respondents said that

e-commerce is not chang-

ing the way they process

returns at all or not very

much. Another 22% said

that it is only changing

their processes to some

extent. Only 16% said that

e-commerce is changing

their reverse logistics pro-

cesses to a great extent.

Of those who believe that e-commerce will affect their overall

business operations in the next two years, 57% believe they

will improve while only 3% believe they will deteriorate.

Of those respondents making plans to deal with more

returns in the future, 26% are increasing their ware-

house space, 22% are adding part-time labor and 16%

are adding full-time labor, 22% have set up a dedicated

department to handle e-commerce returns and 11% are

outsourcing the function.

Given that e-commerce fulfillment has had

a tremendous impact on order fulfillment and

transportation strategies, we believe that it is only

a matter of time before reverse logistics organiza-

tions will need to rethink their operations.

The Internet of Things (IoT) is also heavy in the

supply chain discussion about the future. When

it comes to return rates, only 20% of respondents

believed that IoT is a driver to a great extent (7%) or

to some extent (13%). The vast majority, 70%, said

that it is not having much, if any, impact and 10%

don’t yet have an IoT strategy.

Those who do think that IoT is affecting their

business said they are getting more analytics and

data about sales, that IoT is providing more trans-

parency and that they are using IoT data to predict

and resolve failure events before they become an issue,

reducing the need for returns.

Looking forward

Whether your organization is a manufacturer, wholesale

distributor, retailer or e-tailer, returns are ingrained in the

customer experience. Whether it’s the ease of doing a

return with Amazon, lib-

eral return policies from

fashion and apparel com-

panies or the fact that

service on electronics

and appliances is often

done by third parties,

business customers and

consumers alike judge

the companies they do

business with by their

returns experience.

Our survey respon-

dents clearly recognize

FIGURE 4

How do you handle refurbished and returned

items that are in re-sellable condition?

Peerless Research Group (PRG)

Liquidation sales 56%

Goes back on the shelf 56%

Sell to a discount retail chain

(such as Job Lot, Big Lots, BLINQ, etc.)

21%

Auction off 18%

We have a dedicated website/page

on our website for these items

9%

Other* 38%

* Charitable donations, clearance/outlet stores, destroy,

employee sale/giveaway, refurbished and discounted

FIGURE 5

How well prepared is your

reverse logistics platform to handle

a growing e-commerce business?

Peerless Research Group (PRG)

Very prepared 28%

Somewhat prepared 53%

Not very/Not at all prepared 19%

scmr.com S u p p l y C h a i n M a n a g e m e n t R e v i e w • M a y / J u n e 2 0 1 8 29

that fact: 75% agreed that reverse logistics is a key com-

ponent to a streamlined supply chain and only 3% stated

that reverse logistics is a waste of time. At the same time,

there was a complacency among respondents, where

only 24% disagreed with the statement that their reverse

logistics process needs to be re-engineered and only 39%

disagreed that their process for handling returns lacks

focus. Many more were in the middle—they didn’t know.

In an earlier question, only 33% indicated that their pro-

cesses needed improvement. Clearly—or maybe not so

clearly—it is a mixed bag.

When we asked what had changed in their reverse

logistics operations over the last two years, 56% said

that they had improved, but 41% said there had been

no change at all with the remainder saying they had

deteriorated. Driving those changes was a need to

improve efficiencies (53%), more demanding custom-

ers (44%), the volume of returns (38%), and the vol-

ume of sales (23%).

When we asked how their processes will change

over the next two years, we received almost identical

responses: 57% expect them to improve, through better

tools to forecast, track and manage returns. At the same

time, 40% expect no change at all, and the rest expect

them to deteriorate.

In reviewing the results, we came to two important con-

clusions. The first is that, as with U.S. Cellular, those respon-

dents with a focus on reverse logistics are realizing benefits

that have an impact on their bottom lines. Yet, too many

respondents indicate that they aren’t paying close enough

attention or don’t have enough resources. One example:

Liquidation was the second most common way of handling

returned items in a re-salable condition. While that might be

a simple solution, it’s leaving money on the table.

Those findings are consistent with the experiences of

the two organizations that co-sponsored this research,

WERC and the Reverse Logistics Association.

Tony Sciarrotta, the executive director of the Reverse

Logistics Association and a former reverse logistics

executive at Philips Electronics, was struck that more

than two-thirds of respondents (68%) said that no one at

the corporate level in their company was responsible for

reverse logistics. “During my 15 years at Philips, every-

one knew that I was accountable for returns,” says Sciar-

rotta. “If no one knows who is responsible, it doesn’t get

fixed.” He also noted that 42% of respondents said that

reverse logistics was somewhat or not very important to

their organizations. “What we do matters to your organi-

zation’s bottom line, and not enough respondents said it

was important.”

Michael Mikitka, the CEO of the Warehouse Educa-

tion Research Council, similarly noted the number of

respondents that said they lacked resources for their

reverse logistics operations. “Those who are paying

attention are experiencing a benefit, but not enough

organizations are putting resources into their opera-

tions,” he said. He also noted that 70% of respondents

said they were somewhat or not prepared to handle a

growing e-commerce channel. Yet, we all know that

e-commerce is only going to grow as a sales chan-

nel, resulting in even more returns. At the same time,

Mikitka saw the glass half full. “When those companies

that are doing it right see improvements in key areas

that affect their bottom lines, such as reducing costs

and waste, those are opportunities,” he said.

The second is to repeat the axiom that what gets

measured gets managed. When only 27% said they

could quantify the impact on annual revenues, that

means that most don’t understand their end-to-end

costs. That makes it difficult to justify investments that

can improve operations. jjj

* You can read the complete survey results on scmr.com.

When we asked what had changed in their reverse logistics operations over the

last two years, 56% said that they had improved, but 41% said there had been

no change at all with the remainder saying they had deteriorated. Driving those

changes was a need to improve efficiencies (53%), more demanding customers

(44%), the volume of returns (38%), and the volume of sales (23%).

Copyright of Supply Chain Management Review is the property of Peerless Media and its

content may not be copied or emailed to multiple sites or posted to a listserv without the

copyright holder’s express written permission. However, users may print, download, or email

articles for individual use.

IN-FOCUS

Linking Supply-Chain Improvements

t o Enhanced Financial Performance

Management consulting and technology services company

Accenture in conjunction with research universities Stanford

and INSEAD has released giobai research that iinks supply-chain

performance with a company’s enhanced financial performance.

Accenture, Stanford and INSEAD analysed financial data

from more than 600 global companies and applied statistical

models to assess supply-chain performance relative to

market-capitalisation growth. The results confirm that supply-chain

excellence is rewarded. Supply-chain leaders – companies with

frequent inventory turns, low cost of goods soid as a

percentage of revenue and high return on assets – were

shown to have a market capitalisation compound annual

growth rate (CAGR) 7-26 percentage points higher than their industry

averages. At the same time, the market cap CAGRs of companies

with poorly performing supply-chains trailed the industry

average growth rate by up to five percentage points. These results

were consistent across nearly all of the 24 industries studied.

“The supply-chain is an area of tremendous growth

opportunity and an increasingly frequent target of senior

executive attention,” says William Copacino, Managing

Partner of the Accenture giobai supply-chain management

practice. “A growing number of companies are iooking to the

supply-chain to help transform their cost structures, open new

channels and fundamentally improve their lousiness. This

study validates those choices with clear evidence that superior

supply-chains enhance companies’ ability to grow.”

Additionally Accenture, Stanford and INSEAD consulted

industry analysts and academic experts, and conducted

in-depth interviews with more than 75 executives from 60

companies to identify and document the success factors that

lead to supply-chain dominance. They developed a

Web-based survey to capture the supply-chain insights and

experiences of leading executives from more than 100

companies across North America and Europe.

Results in this area indicate that executives universally

recognise the value and impact of supply-chain management.

In fact, nearly 90% of respondents stated that the

supply-chain is very important, or critical, to their business.

Overall assessments of supply-chain importance to North

American and European respondents received similar ratings.

However, the research also revealed that executives from

North America were significantly more likely than their

European counterparts to designate supply-chain

management as critical – 57% versus 32%.

The enquiry also focused on supply-chain transformation:

how leading companies incorporate supply-chains into their

business strategies; how supply-chain innovation is reflected

in companies’ operating models; how supply-chain leaders

execute against their strategies and capabilities and adapt

them to changing market needs. The report analyses and

discusses the operating strategies of more than 20 leading

companies, including: 7-Eleven, Coca-Cola, Dell, DuPont, U & Fung

and Nokia. The document also introduces a template for

suppiy-chain transformation, identifies key success factors

that are common to all supply-chain transformation efforts

and looks into the future to project the influence of

supply-chain transformation on the evolving business landscape.

About the research

Accenture began with a detailed analysis of public

disclosure data from selected Global 3000 corporations,

classifying companies into supply-chain leaders, transformers,

decliners and laggards based on their supply-chain

performance profiles over time. It then statistically related

these supply-chain categories to shareholder value growth

rates and pattems over time. Accenture also conducted more

than 60 in-depth interviews with executives responsible for

supply-chain strategy and operations. The interviews

complemented an online survey of 104 additional

supply-chain executives in North America and Europe

representing companies in more than 25 industries.

The report includes case studies on a number of

companies including Thames Water, Nokia and Spanish

clothing manufacturer/retailer Zara.

Further information and a free copy of the report,

contact: Sarah Jones, Accenture.

Email: 5arah.c.jones@accenture.com

Web site:www.accenture.com * ^

Single Source Supply Chain Solutions

Warehouse Management Software

Swisslog’5 software solutions provide the real time dat3 required to execute your supply chain and

include, warehouse management, automation management systems and supply chain simulation.

SwJsslog plans, designs and realises the supply chain concept according to your needs: from efficient

Software products, turnkey logistics solutions, to materials automation technology.

Swissiog Software (UK) Lsd ; ^

706 Stifling RoaC Over 2000 successful installations prove our broad know-how and we accompany you during t h ^

Sbugh 5L1 4SY whole lifetime of your systems as a consultant and service partner – in 23 countries worldwide.

Tel. 01753 528545

es.softwa re. u k@swisslog.com

w w w.swisssiog com swisslog

Essay Writing Service Features

Our Experience

No matter how complex your assignment is, we can find the right professional for your specific task. Achiever Papers is an essay writing company that hires only the smartest minds to help you with your projects. Our expertise allows us to provide students with high-quality academic writing, editing & proofreading services.

Free Features

Free revision policy

$10Free bibliography & reference

$8Free title page

$8Free formatting

$8How Our Dissertation Writing Service Works

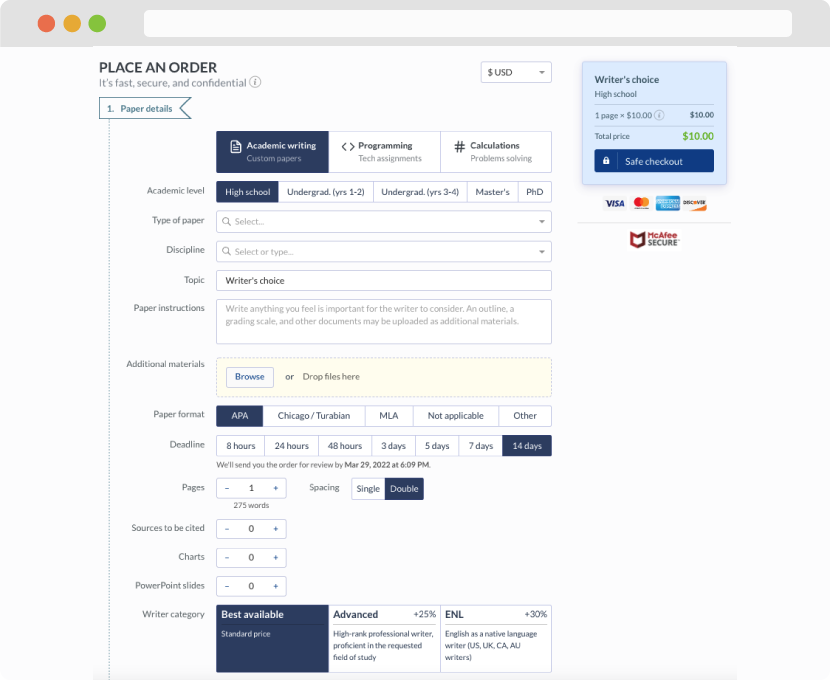

First, you will need to complete an order form. It's not difficult but, if anything is unclear, you may always chat with us so that we can guide you through it. On the order form, you will need to include some basic information concerning your order: subject, topic, number of pages, etc. We also encourage our clients to upload any relevant information or sources that will help.

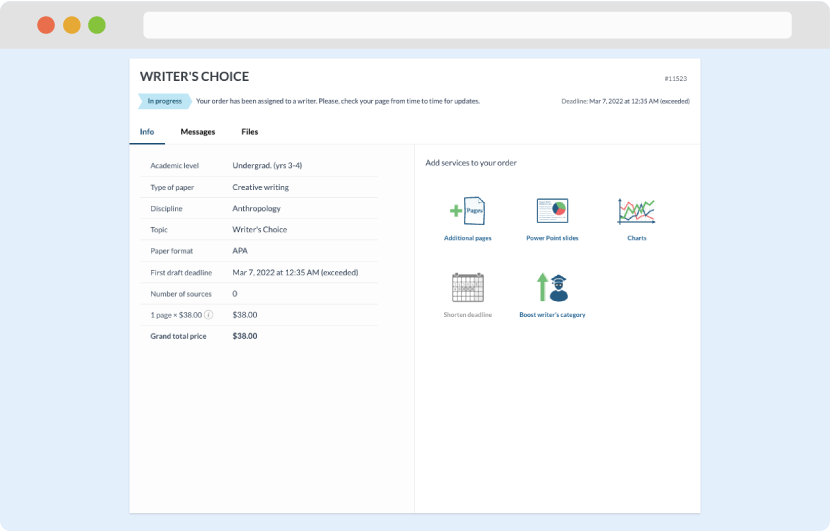

Complete the order form

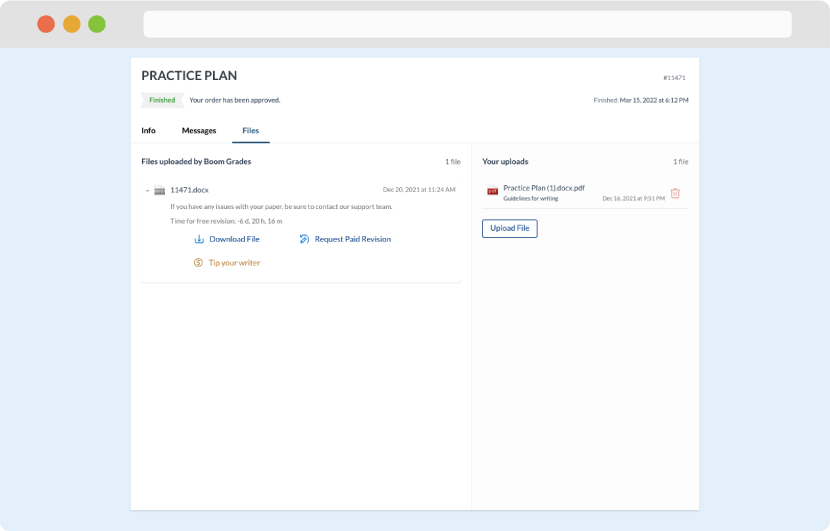

Once we have all the information and instructions that we need, we select the most suitable writer for your assignment. While everything seems to be clear, the writer, who has complete knowledge of the subject, may need clarification from you. It is at that point that you would receive a call or email from us.

Writer’s assignment

As soon as the writer has finished, it will be delivered both to the website and to your email address so that you will not miss it. If your deadline is close at hand, we will place a call to you to make sure that you receive the paper on time.

Completing the order and download